- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

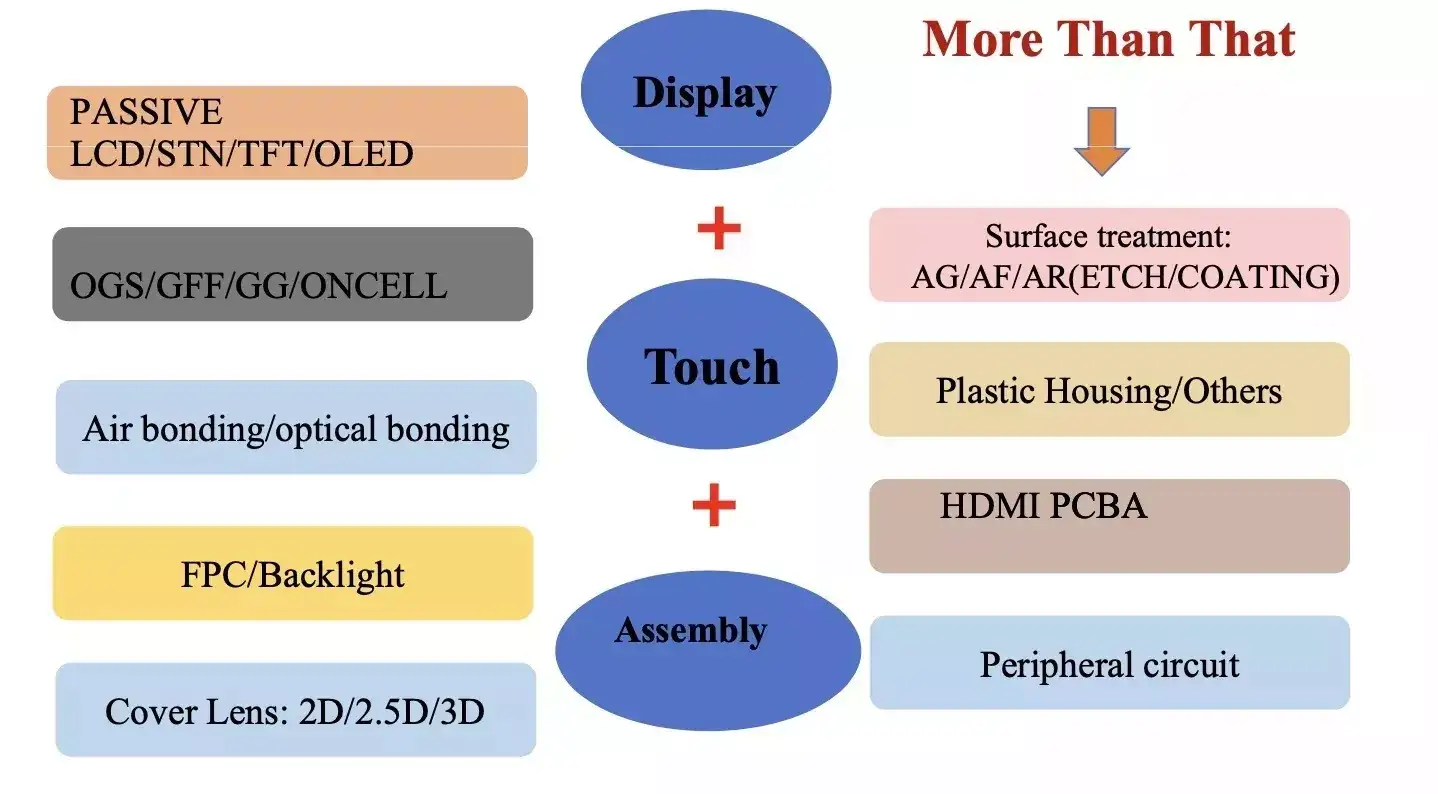

Our Advantages

Our Product and Technical skills

Sunlight readability of Display

The best solution to direct sunlight readability is transflective LCD. But the transflective LCD display compromises the transmission rate and the contrast because it needs an additional reflective layer, not to mention the high cost problem, so the transflective LCD panel is not a popular or practical solution because of these issues.

We usually use below technologies to help customer solve the problems at an affordable cost.

1. High Brightness LCD panel

2. Optical Bonding

3. Anti-reflection surface treatment

4. UV protective film & IR heat rejected

5. Ventilation Structure Design

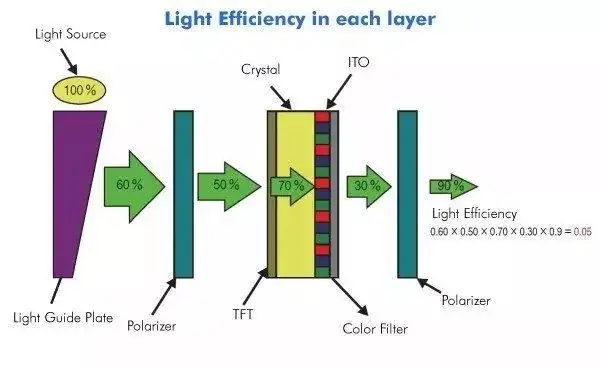

1. High Brightness LCD Panel

Two solutions for the high brightness requirement:

1.1 High Efficient LED Light Bar Replacement

Replace the original CCFL or LED light bar with a high-efficient LED light bar to increase brightness, also eliminating the inverter thereby improving EMI emissions.

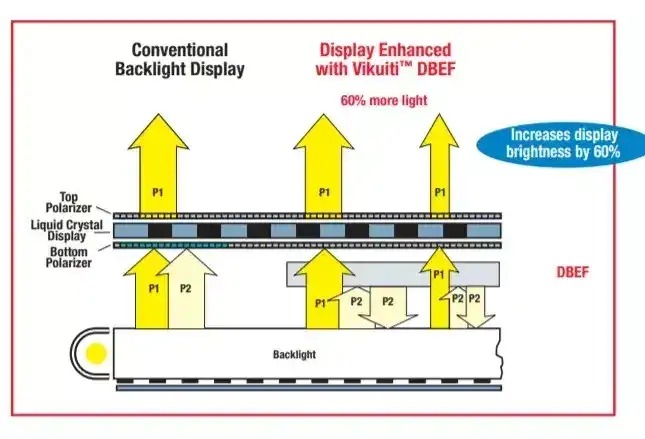

1.2 Brightness Enhancement Film Replacement

DBEF is known for significantly increasing display brightness while maintaining excellent image quality and energy efficiency, DEBEF captures and ulitilizes light normally lost to absorption in the bottom LCD polarizer. It is able to provide an on-axis brightness increase of 165% in slab light guides, and 277% in wedge light guide displays, when combined with other Brightness Enhancement Films. This increased brightness can be converted into power saving.

Possible applications for high brightness displays:

▶ POS/ Signage

▶ Ticket machine/ ATM

▶ E-mobility

▶ Transport

▶ Marine

▶ Portable devices

▶ Broadcasting

▶ Construction/ agriculture

▶ etc.

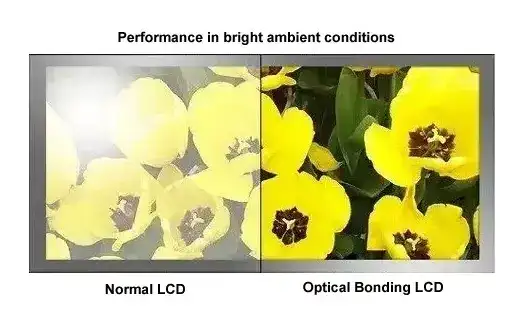

2. Optical Bonding

Optical bonding is the joining of two rigid optical elements using transparent adhesive to reduce reflectance and provide vandal resistance.

Optical Bonding Benefits:

Increased sunlight readability up to 400%

Increased impact resistance up to 300%

Enables resistance to extreme temperatures

Enable thinner and lighter display designs

Prevents condensation and fogging

3. Anti-reflection surface treatment

The readability of an LCD display under direct sunlight is strongly correlated with the reflection of LCD surface. A reflective surface of the display will make the readability worse even with high brightness. A proper anti-reflection surface treatment is important to improve the readability.

4. UV Protective film & IR heat rejected

Ultraviolet (UV) rays are invisible rays that are part of the energy that comes from the sun. An LCD panel can be damaged by UV rays if it is exposed too much to the sun.

A proper UV protective film is crucial for the sustainability of an LCD display under direct sunlight.

The Infrared light contribute heat to cause the overheat problem. A proper Anti-IR solution is also crucial for the sunlight readable issue.

5. Ventilation Structure Design

Another issue for outdoor direct sunlight applications is the overheat issue. Overheating causes the crystal to liquidize, which results in the black image. In a direct sunlight application, the ventilation structure design is more crucial because infrared light and visible light contribute heat on the LCD panel. Without the appropriated ventilation design, a LCD display won’t survive the overheat problem.

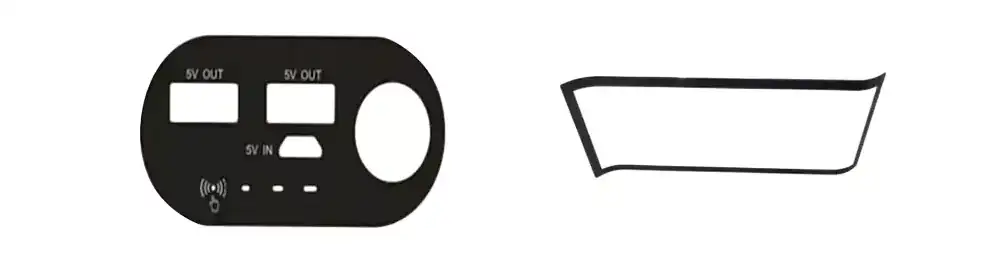

Customized Cover Lens

Thickness: Depending on the material and brand, we can offer thicknesses from 0.6mm up to 10mm.

Surface Treatments:

● Anti-Glare (matt): etched or coated

● Anti-Glare: etched or coated

● Anti-Finger print: etched or coated

● Water-proof: etched or coated

● Hard-coating: up to IK10

● Touch with gloves

Shape and Surface Adaptations:

edge processing (e.g. C-edge polished or sanded, bevelled edge, etc.), drilling, recesses, hollows or 3d glass

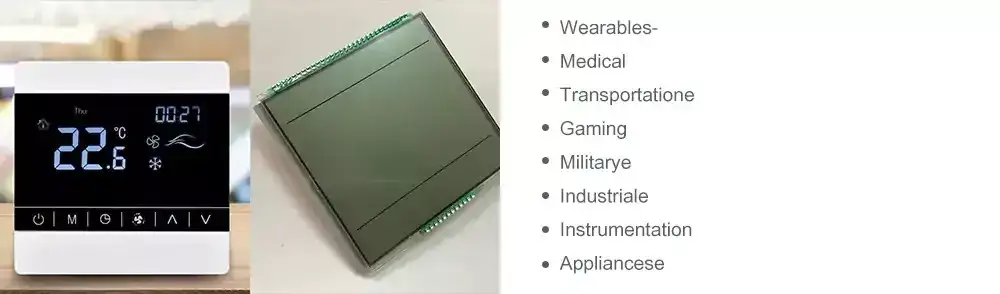

Passive LCD displaly

A passive LCD is a low cost option when a display is needed for an application that doesn’t require high performance. The passive matrix lcd has a grid of horizontal and vertical wires and at the intersection there is an LCD element that makes a single pixel. But the active-matrix LCD has a transistor on each pixel, which allows for more contrast, higher resolution and faster response time.

Possible applications for passive lcd displays:

Our RD team will work with you to make sure you get the right display solution for the product that you are designing, TN, HTN, FSTN, STN, VA can be chosen according to your need.

OLED display

OLED can be divided into active matrix (AM) and passive matrix (PM) design. In industrial field, we mostly use passive matrix OLED displays (PMOLED), and it has been proved to be the best display technologies for applications with small diagonals. Our OLED ranges from 0.96" to 5.5" and have both monochrome color variants and various full color variants. There is no need for backlighting due to the self-luminous characteristic of the OLED.

Currently we offer the following OLED Displays:

· Transparent

· Round

· Monochrome

· Full color

· Area Color

· Character Type

Peripheral circuit design

Our RD team can also help customer to design Peripheral circuit to realize special requirements, eg DC-DC converter, backlight adjustment, interface transfer.

● DC-DC converter

● backlight adjustment

● MCU to RGB interface transfer

● MIPI to RGB interface transfer

● RGB to MIPI interface transfer

● LVDS to RGB interface transfer

● HDMI to RGB & LVDS with scaler interface transfer

● HDMI to MIPI interface transfer