- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why should the Cover Lens be printed with anti-UV ink?

2025-07-18

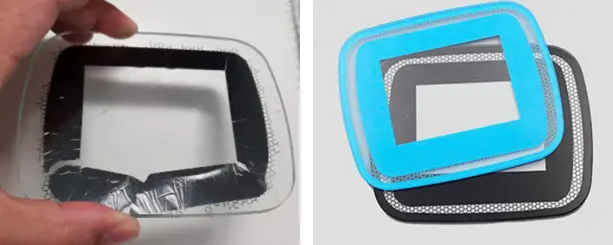

Without anti- UV ink VS With anti- UV ink

Touch screen cover (Cover Lens) printing anti-UV ink is mainly to solve the various negative effects caused by ultraviolet radiation and ensure the long-term reliability, aesthetics and functionality of the touch screen.

Here are a few key reasons:

1.Prevent material degradation (yellowing, embrittlement):

The cover lens is usually made of transparent polymer materials, such as PMMA/acrylic, PC or tempered glass (although the glass itself is UV-resistant, the adhesive on its edges or back may not be).

These organic polymer materials will undergo photochemical reactions (photo-oxidative degradation) when exposed to sunlight or strong artificial light sources (especially the ultraviolet band) for a long time.

Consequences:

Yellowing: The material gradually turns yellow, seriously affecting the display effect and appearance of the screen. The originally clear and transparent cover lens becomes turbid and yellow.

Embrittling: The molecular chain of the material breaks, causing the cover lens to become brittle, the mechanical strength to decrease, the impact resistance to weaken, and it is more likely to break.

Cracking: Severe embrittlement can cause cracks on the surface or inside of the cover lens.

The role of UV-resistant ink: UV-resistant ink contains special pigments (such as titanium dioxide, zinc oxide) and UV absorbers/stabilizers that can absorb or reflect ultraviolet rays. They form a barrier that prevents or greatly reduces the penetration of ultraviolet rays into the cover material, thereby effectively delaying or even preventing yellowing, embrittlement and cracking.

2.Protecting internal components:

The internal structure of the touch screen is complex, including a transparent conductive layer of ITO (indium tin oxide) or other materials (for detecting touch), optical glue (OCA), polarizer, liquid crystal layer (if it is an LCD screen), and even an organic light-emitting layer (if it is an OLED screen).

Consequences:

Damage to the conductive layer: Ultraviolet rays may affect the performance or structure of conductive films such as ITO.

Adhesive failure: Ultraviolet rays can cause adhesives such as optical glue to age, yellow, lose viscosity or produce bubbles.

Display material damage: For OLED screens, ultraviolet rays will accelerate the degradation of organic light-emitting materials, resulting in reduced brightness, color deviation, and shortened life. For LCD screens, polarizers and liquid crystals may also be affected by ultraviolet rays.

The role of anti-UV ink: By blocking ultraviolet rays from the edge of the cover lens to enter the interior, these sensitive components are protected from damage by ultraviolet radiation, ensuring long-term stability of touch function and display performance.

3.Improve optical performance and user experience:

Reduce stray light/glare: The edge of the cover lens usually needs to be printed with black or other dark border ink (BMV) to hide the internal wiring, components, adhesive layer, and improve the visual contrast of the screen. Anti-UV ink is usually a functional upgrade of this border ink.

Consequences: If the border ink itself is not UV-resistant, it will fade, discolor (such as black to gray, purple), reduce adhesion or even fall off under ultraviolet light.

The role of anti-UV ink: Ensure that the color of the border is stable for a long time without fading or discoloring, and maintain the beauty of the screen and good visual contrast. Faded or discolored borders will seriously affect the appearance quality of the product.

Therefore, anti-UV ink is a critical functional coating process for modern touch screens, especially for devices that need to cope with outdoor or strong light environments. It is directly related to the quality, life and user experience of the product.