- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

In-depth Analysis of LCD Mura: Causes, Mechanisms and Improvement Strategies

In the global display technology market, LCD (Liquid Crystal Display) remains the core choice for consumer electronics, industrial control, automotive displays and other fields due to its mature technology, stable performance and high cost-effectiveness. However, Mura (a Japanese term meaning "unevenness"), a common visual defect in LCD products, not only seriously affects screen uniformity and user experience but also may lead to quality disputes and cost losses in foreign trade orders. Today, we'll delve into its causes, principles, and solutions to help you better understand LCDs and bring a better visual experience to global users.

Deeply understanding the formation mechanism of Mura and establishing a full-link improvement system have become key issues for the display industry to enhance product competitiveness.

I. Core Causes of LCD Mura: Multi-dimensional Traceability from Manufacturing to Application

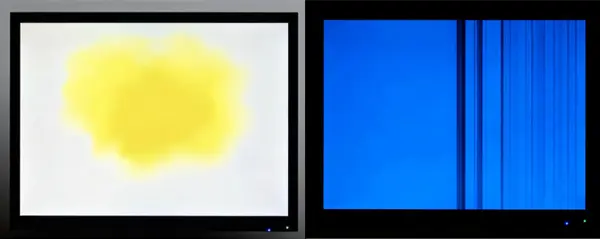

LCD Mura manifests as color deviation, uneven brightness or patchy abnormalities on the screen, which are particularly obvious under monochromatic backgrounds (especially white and grayscale screens). Its causes run through the entire process of product manufacturing, transportation, storage and terminal application.

(1) Precision Defects in Manufacturing Processes

The multi-layer structure of LCD (including backlight, liquid crystal layer, color filter, alignment film, etc.) requires dozens of precision processes. Even minor deviations in any link may induce Mura. Impurity residue due to inadequate substrate cleaning and deviations in color filter alignment accuracy (a deviation of ±1μm can affect display) will cause pixel RGB ratio imbalance; bubbles or uneven molecular arrangement during liquid crystal injection, as well as moisture intrusion caused by insufficient sealant tightness during packaging, will damage the optical consistency of the liquid crystal layer; uneven distribution of spacers (key components controlling cell gap) directly leads to abnormal Cell Gap (liquid crystal cell thickness), forming brightness or color patches.

(2) External Effects of Mechanical and Environmental Stress

LCD modules are extremely sensitive to external stress. Squeezing and dropping during transportation, or insufficient gap during whole-machine assembly, can cause Cell Gap to decrease under pressure—when the pressure is high, the transmittance of RGB three primary colors is significantly reduced, forming black spots; when the pressure is moderate, the transmittance of red and green light decreases more obviously, while blue light is relatively prominent, resulting in blue spots. In addition, high temperature and humidity environments accelerate the aging of liquid crystal molecules and the attenuation of alignment film performance, while electrostatic discharge (ESD) may damage the drive circuit, indirectly inducing Mura-like defects.

(3) Abnormal Performance of Drive and Materials

Drive circuit failures are important electrical causes of Mura. Short circuits of TFT (Thin Film Transistor), line oxidation or inconsistent impedance will lead to signal transmission disorders, resulting in abnormal color control of corresponding pixels. Material defects cannot be ignored either—damage to the dot matrix of the backlight guide plate, local transmittance differences of polarizers, or insufficient purity of liquid crystal materials may be amplified into visible Mura through optical transmission.

II. Core Mechanism of Mura Formation: Synergistic Imbalance of Optics and Structure

The display essence of LCD is the process of regulating light transmittance and color combination by controlling the deflection of liquid crystal molecules through electric fields. The formation of Mura is essentially the failure of this synergistic mechanism.

During normal operation, white light emitted by the backlight is homogenized by the diffuser film, converted into polarized light in a single direction through the polarizer, then deflected by the liquid crystal layer, separated by the color filter, and finally forms uniform colors. When the Cell Gap changes due to squeezing or uneven spacer distribution, the deflection angle of liquid crystal molecules deviates from the designed value, leading to abnormal light transmittance and polarization state—a decrease in Cell Gap changes the optical path difference, causing imbalance in the absorption ratio of RGB light of different wavelengths and forming color deviation; an increase in Cell Gap may lead to yellowish Mura.

In addition, drive circuit failures cause local electric field distortion, preventing liquid crystal molecules from deflecting as instructed, resulting in brightness or color contrast between the pixel in this area and the surrounding area; impurity or moisture intrusion destroys the arrangement stability of liquid crystal molecules, forming irregular optical scattering areas, which appear as cloud-like or dot-like Mura.

III. Systematic Improvement Strategies: From Source Control to Terminal Guarantee

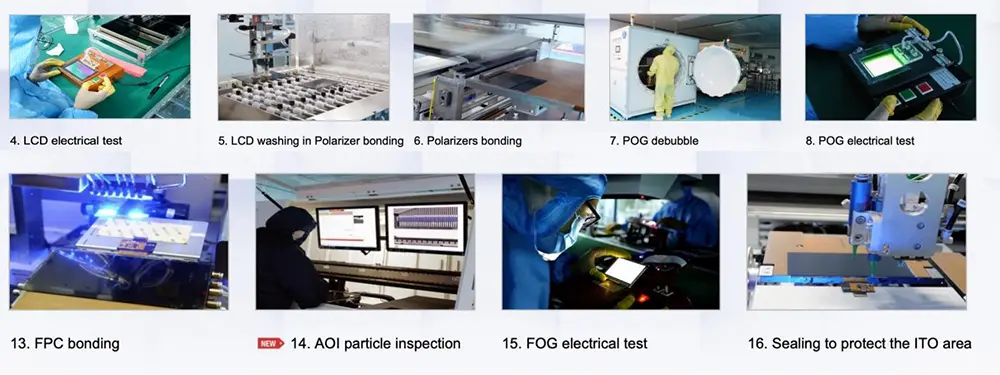

The solution to Mura requires establishing a full-link system of "prevention-detection-repair-optimization", combining manufacturing process upgrading, quality control standard strengthening and application scenario adaptation to achieve quality closed-loop.

(1) Manufacturing End: Process Optimization and Source Prevention

● Upgrade precision manufacturing equipment: Adopt high-precision substrate cleaning systems (such as plasma cleaning technology) to reduce impurity residue rate, introduce automatic color filter alignment equipment to control alignment accuracy within ±0.5μm; optimize liquid crystal injection process to reduce bubble generation.

● Strengthen in-process quality control: Deploy machine vision inspection systems after key processes, combined with JND (Just Noticeable Difference) quantitative analysis, to achieve accurate identification of Mura defects; conduct 100% inspection on spacer distribution and Cell Gap uniformity to avoid defective products flowing into the next process.

● Upgrade material control: Select high-purity liquid crystal materials and high-quality alignment films, filters, establish supplier material sampling inspection mechanisms, and eliminate batch problems caused by raw material defects.

(2) Supply Chain: Packaging and Transportation Protection

For the long-distance characteristics of foreign trade transportation, adopt anti-static and anti-squeezing buffer packaging design, add hard protective layers between modules and packaging boxes to avoid external impact during transportation; control the temperature and humidity of the packaging environment (recommended 15-30℃, humidity 40%-60%) to prevent moisture intrusion. At the same time, optimize the structural design during whole-machine assembly to ensure a reasonable Z-direction gap between the LCD module and the casing, avoiding local interference and compression.

(3) Terminal End: Application Guidance and After-sales Support

Provide LCD usage guidelines to overseas customers, clarify environmental adaptation requirements (avoid high temperature and humidity, stay away from strong electrostatic sources); advise customers to use soft tools during assembly to avoid direct screen extrusion. Establish a rapid after-sales response mechanism, provide technical analysis and return and exchange support for orders with Mura problems, and collect terminal feedback to reverse optimize product design.

Conclusion

The essence of LCD Mura is the result of the synergistic effect of precision optical systems and external factors. Its solution relies not only on technological upgrading but also on establishing a full-chain quality control mindset. In the context of increasingly fierce competition in the global display market, continuously reducing the Mura defect rate through process optimization, precise detection and full-cycle services is the core path for display enterprises to enhance foreign trade competitiveness and win customer trust. With the continuous iteration of technology, we have reason to believe that the display quality of LCD products will continue to break through, bringing a better visual experience to global users.